Engine Bearing Replacement Service

$30.00 – $40.00

Bearing replacement is $30-$40 depending on which bearing option you select plus the return shipping or you can provide a return label.

When sending in your engine for Bearing replacement:

Please make sure to include your name, return address, email address, and a short description of the service needed inside the box.

I’ll need the complete engine and carburetor only, please do not include the exhaust or clutch system.

Thank you,

Adam

Please send engines to:

Attention: Adam Drake

600 W. Avenue L #231

Calimesa, Ca. 92320

For International shipping or questions please contact: thedrakeracing@gmail.com for more information.

SKU: N/A

Category: Engine Services

- Description

- Additional information

Description

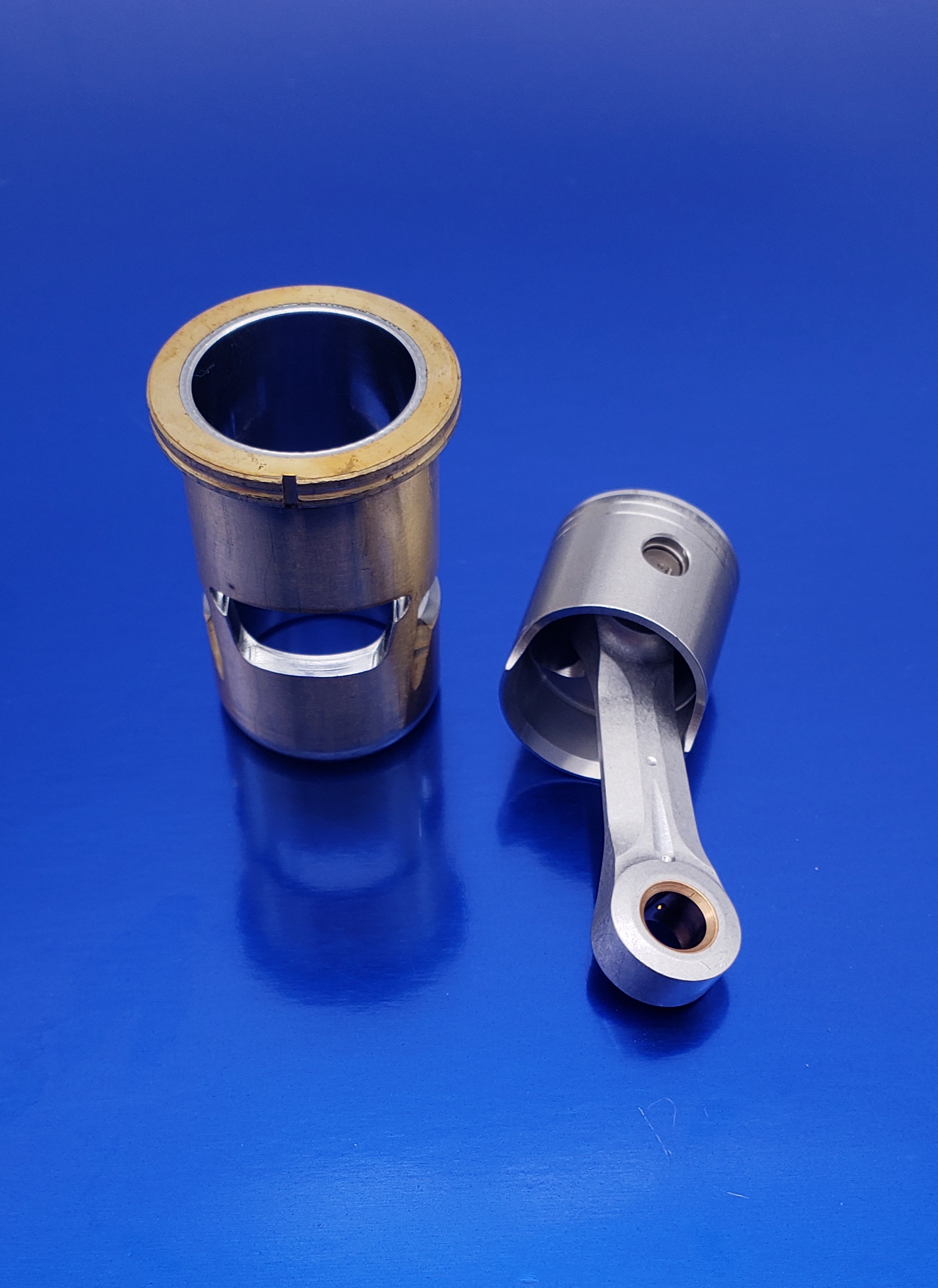

Engine bearings have a critical role in your engine’s performance and reliability. If you notice any bearing noise or leaking from the front bearing, it’s time to replace the bearings to keep your engine running in tip top shape.

Ceramic bearings have many advantages over standard steel bearings, such as decreased weight, higher RPM capabilities, increased corrosion and wear resistance, as well as reduced friction and vibration.

Advantages of Ceramic:

-

High Speed: Hybrid Bearings can reach a resistance level of 1,200,000dN with grease lubrication, due to reduced slip, wear extent and heat productivity.

-

Lightweight: The weight of ceramics is 60% lighter than steel, which decreases the centrifugal force and overall weight.

-

Long Service Life: The service life of Hybrid Bearings is 3 to 5 times longer than that of steel in comparable working conditions.

-

Self Lubricating: Even when poorly lubricated or with no lubrication, ceramic bearings will continue to function longer than steel under the same level of stress due to their self lubricating properties.

-

Corrosion Resistance: Hybrid bearings have excellent corrosion resistance, and will continue to function while corroded.

-

High Rigidity: The elastic ration of ceramics is 1.5 times greater than that of steel, this dramatically increases the rigidity of the balls.

-

Low Friction: Ceramic materials have a low friction force. Even under the conditions of boundary lubrication, the surfaces are extremely smooth, so its friction force is low and the rotational friction moment is low.

-

Wear Resistant: The micro-hardness of ceramics can reach a Vickers Hardness level of HV1700 kg/mm2

Additional information

| Weight | 1.2 oz |

|---|---|

| Dimensions | 6.5 × 5 × 4 in |

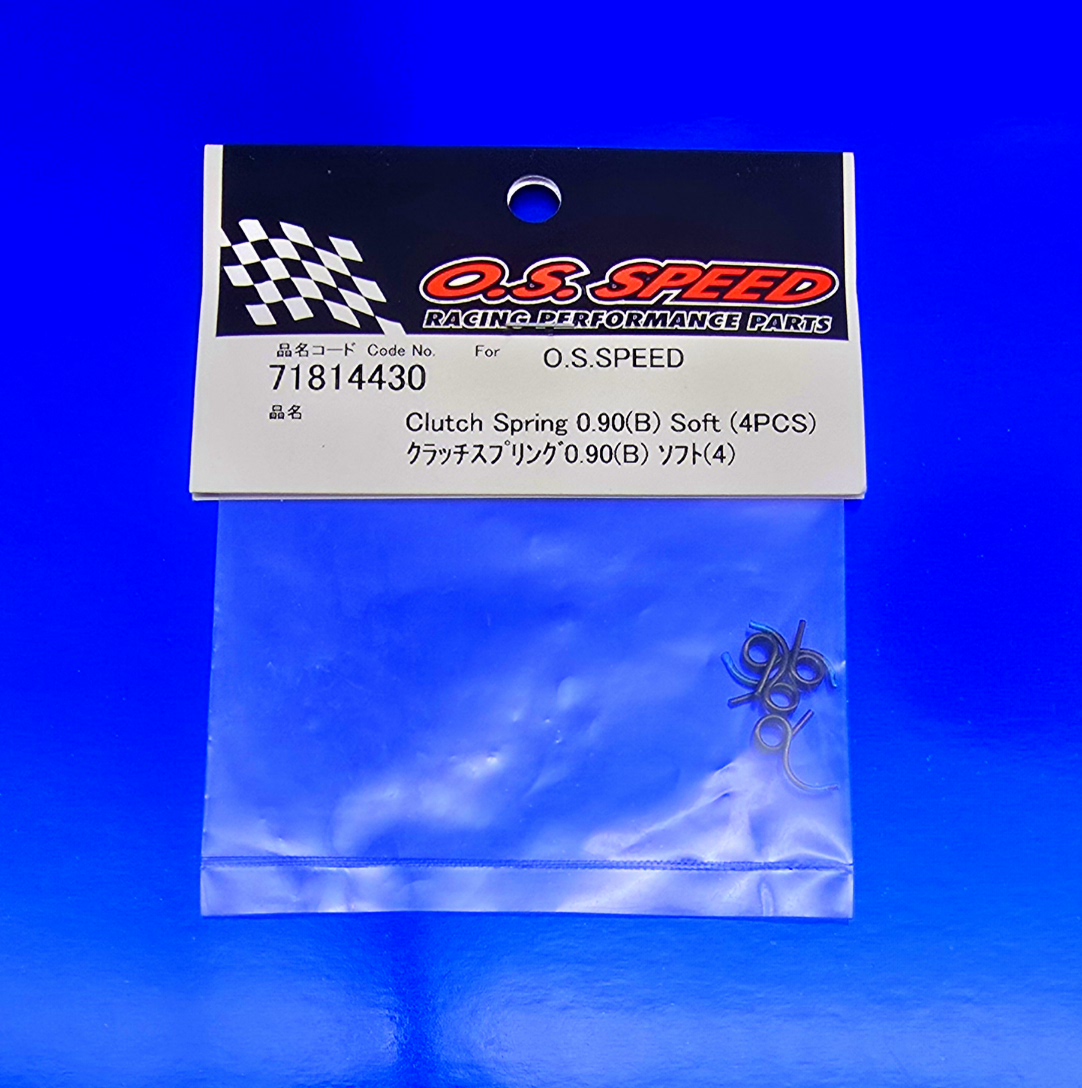

| Bearing Options | Steel Front/Steel Rear, Steel Front/Ceramic Rear |

FEATURED PRODUCTS

Engine Break In Service

$50.00

Sleeve Resizing Service

$25.00

Engine Bearing Replacement Service

$30.00 – $40.00